Loading... Please wait...

Loading... Please wait...How Do Industrial Dust Collectors Work?

Posted on 18th May 2017

This simple question is asked by many PCS customers on a daily basis. Most companies are familiar with the concept of blowers and ducting, but integrating a dust collection system and understanding all of its components can be confusing. Hopefully this article provides some clear, concise understanding about the inner workings of a dust collection system and why you should choose one type over the other.

Industrial dust collector design

In the simplest form, a dust collection system is designed to purify air or gas by removing the contaminants or dust particulate from the collected air. Dust collectors can be categorized into 4main types, Inertial Separators, Filtered Collectors, Wet Scrubbers and Electrostatic Precipitators.

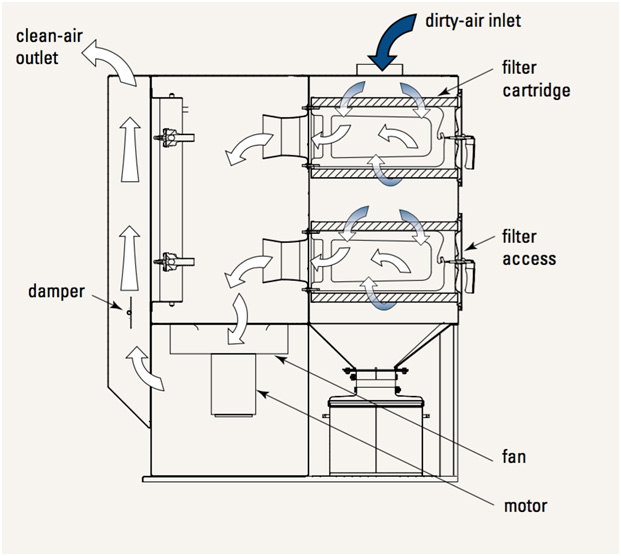

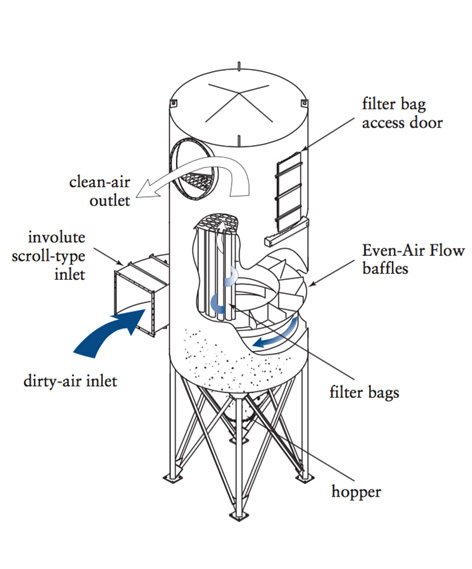

Most types of dust collectors have ducting that is connected to the inlet of a collector, a means for filtering the dirty air inside of the unit, a blower system for creating airflow through the ducting system and internal body of the dust collector,a cleaning system for the filters and a discharge mechanism for capturing the dust particulate for either waste or reclaim purposes. All of these components will vary slightly based on the application,simplifying these foundational key items to dust collection systems.

What’s the best dust collector?

Due to the fact that there’s a wide selection of brands and types of dust collectors on the market, it is important to narrow down the search based on a few key questions that must be answered: What is your application? Is your dust collector going inside or outside? What are the characteristics of the contaminant or dust particulate? Is this collector going to be used continuously or intermittently?

It is hugely important that these basic questions be answered so that PCS can determine and engineer the proper dust collection system for your facility. If you want to have low maintenance costs, low cost of ownership, efficient suction, meet any local or national OSHA/NFPA regulations and create the cleanest work environment possible, proper time and consideration should be taken on each application so that the dust collector works for your individual process needs.

The best dust collector is one that that is sized appropriately, has a good warranty, has a cleaning mechanism that is efficient enough to handle the exact dust that the system is encountering, has a properly engineered ducting system and coupled industrial blower, and has a filtration method in the unit that is efficient enough to handle the type and size of particulate conveying through the unit.

What kind of industrial dust collector do I need?

As stated above,industrial dust collection systems can vary widely, but the below list should help to narrow it down and a PCS sales member or engineer would be happy to further discuss your application so that the correct unit is chosen, along with how the dust collector works. We carry many types of Donaldson Torit dust collectors to work optimally in your application.

Blasting Applications:

Cartridge Dust Collectors

Downflow Workstations

Cabinet Units

Plastics:

Cartridge Dust Collectors

RF Baghouse

DalamaticBaghouse

Foundries:

Cartridge Dust Collectors

Modular Baghouse

Food Processing:

Cartridge Dust Collectors

Modular Baghouse

RF Baghouse

Grain/Agriculture:

Cartridge Dust Collectors

Modular Baghouse

RF Baghouse

Laser/Plasma Cutting:

TD Dust Collector

Cartridge Dust Collectors

Welding:

TD Dust Collector

Cartridge Dust Collectors

Wet Machining:

WSO Mist Collector

MDV Mist Collector

Dryflo

Metal Working:

TD Dust Collector

Cartridge Dust Collectors

Downflow Workstations

Vibra Shake Units

Downdraft Benches

Cabinet Units

Wood Working:

Cartridge Dust Collectors

Modular Baghouse

RF Baghouse

Cyclone